What is Activated Carbon ?

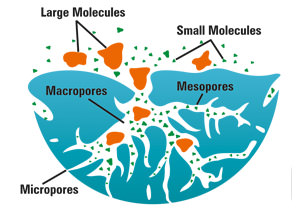

Activated Carbon is a non-graphite form of carbon which could be produced from any carbonaceous material such as coal, lignite, wood, paddy husk, coir pith, coconut shell, etc. Activated carbon manufactured from coconut shell is considered superior to those obtained from other sources mainly because of small macrospores structure which renders it more effective for the adsorption of gas/ vapor and for the removal of colour and odour of compounds.

Activated carbon has the strongest physical adsorption forces or the highest volume of adsorbing porosity of any material known to mankind. Activated carbon can have a surface of greater than 1000m²/g.

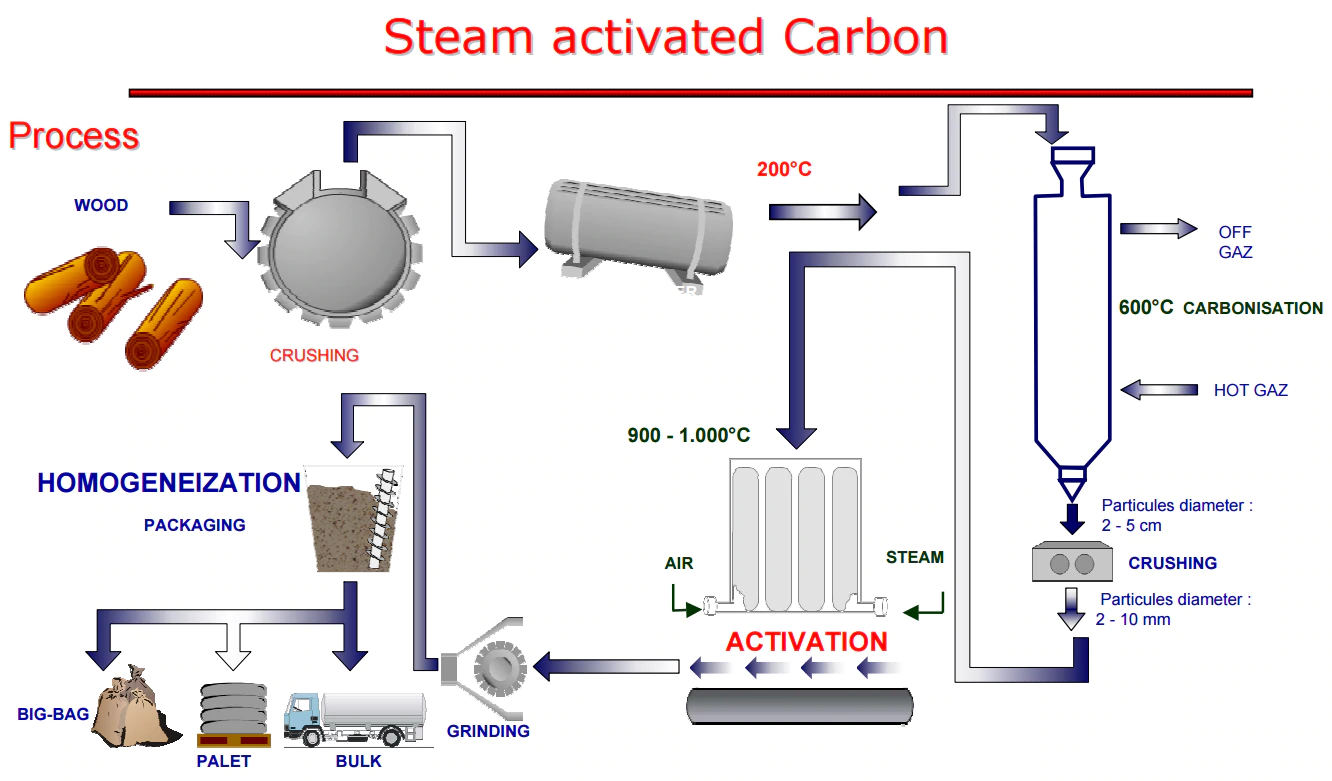

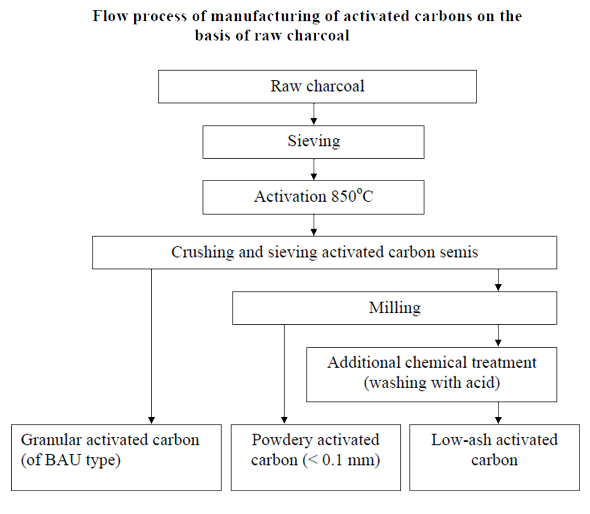

There are two types of processing process.

We manufacture both form of Activated carbon which is commonly used across the world.